The first light I used on patrol was a surefire 6p led. This was a decent light. The technology in led lights advanced quickly and newer more efficient and brighter leds came to the market. One of the great things about the surefire 6p is that it established a standard in the industry for flashlight hosts. The modules that are made for surefire 6p sized bodies became known as p60 modules. Multiple companies began making aftermarket led modules that could be dropped in to 6p bodies. These ranged from low cost modules to high end modules that were made for hard use. I ended up replacing the surefire led module with a Malkoff module. The Malkoff produced much more light and was known for being very tough. Fast forward several years and I started looking at 6p modules again. I was curious what advances had been made in the industry. I found several lights that were claiming around 1000 lumens of output. Most of these lights were using the newest high output led, the cree xm-l2. Many of these lights were made by Chinese companies and they used proprietary light sizes. With this information I knew the technology was available to make a 6p drop in that produces 1000 lumens. I was having a hard time finding a drop in that used the latest technology that was also made for hard use. One particular feature I was looking for is that the module be potted. Be sure to check out the video testing at the end of the review.

Picture of potting on led module.

In this review I am going to discuss several features of lights. Features like lumens, tint, regulation, potting, and beam profile. If you are not familiar with these features I explain them in detail in the first half of the elzetta light review that is also posted on this site.

In my quest for a new p60 module I stumbled upon a company named pflexpro. There was very little information about pflexpro. It is one of the few times I did a google search and the results stopped after 2 pages. I found a few posts by the owner, Randy Brogden on some flashlight forums. Most of his posts were highly technical and involved in depth testing of various flashlight components. Pflexpro tac model can be found at http://www.pflexpro.com/product-p/apd-22m.htm

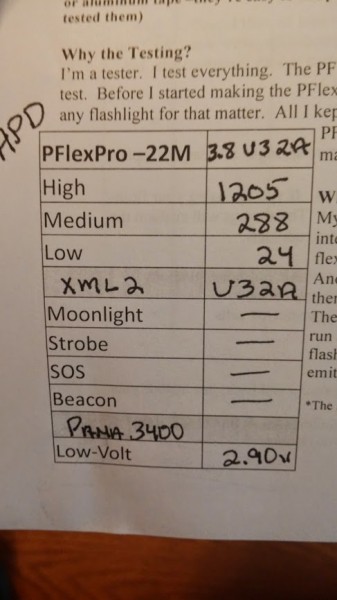

Pflexpro modules stood out for several reasons. The modules were fully potted. They were American made. They had very high output, 1200 lumens. On Randy’s website when you order a module you can pick from a wide variety of features and essentially get a light custom made for exactly what you need. I found one internet post where someone was asking for opinions on pflexpro products. The replies were positive. There was one post where a person took a picture of a document that ships with the module. It had instructions for use but it also included the output of the light. Nearly every light includes lumen output but these specifications looked different.

I decided to order a module and I received a shipping notice the next day. The module arrived in a padded envelope. The module was inside a plastic tube. This tube was placed into a cutout in the middle of a piece of cardboard. The cardboard was then wrapped and sealed in plastic film. The first thing that stood out to me was handwritten lumen output numbers. I learned that pflexpro doesn’t just give approximate numbers for each class of lights. Every single light or module is individually tested before it ships and these numbers are provided with the product. A runtime graph was included that showed the output of my module over 5 minutes.

I began reading the instructions that came with the p60 module. I was thoroughly surprised by the first paragraph. The instructions stated that the drop ins can be upgraded later by pflexpro if a newer led comes out for $15. Pflexpro will also change out the reflector one time for free if you damage yours or decide you want a different style. I have never seen a company offer this kind of service.

There were several features that I wanted in a patrol style light. I was able to get everything I wanted through the options pflexpro offers. My specific light had the following features:

Solarforce L2P host

U3-2A emitter

Orange peel reflector

3.8 amps output

22 mode driver (semi-permanent mode locking the menu added to purchased lights)

Forward clicky switch

Interchangeable contacts

There are some great lights on the market. Unfortunately some of these lights that are designed for police/tactical work are $200 or more. This is a lot of money to spend on a flashlight. The lights I received from pflexpro use a solar force made surefire 6p clone. This is a Chinese made copy of the surefire 6p body that accepts rechargeable batteries. Pflexpro uses these bodies and then produces their own high performance led modules for the lights. It is also possible to purchase a bored surefire made 6p host and use the pflexpro module in it. With the pflexpro combination you get a very affordable light with one of the best led modules on the market.

I wanted the light to be bright. The unit I received from pflexpro makes 1200 lumens in high. For me this is important during traffic stops and working outside. High output lights allow me to see through window tint as well as illuminate a person at distance. If you don’t want 1200 lumens there are lower output options.

Although a bright light is very useful there are times when less than full output is needed. Lower output is nice for looking at things less than arms reach away. It is also nice to have a lower but still bright output for longer runtimes such as working a collision or directing traffic. Many multiple output lights can have confusing or hard to work menus. One thing that was mandatory for my light is that is always comes on high when it is turned on.

The pflexpro module has a unique operating system. The light has 22 menu possibilities. By using a specific number of taps on the light switch the light is set to the mode of your choice. For my light I set it up so that it always comes on high. If the light’s switch is quickly tapped it drops to 15 percent output for around 180 lumens. This level of light is very useful for searching cars or houses. If the light is turned off or the switch is tapped again while on it returns to high mode.

Procedures for changing modes. There are a few different techniques you can use to program the light but this worked well for me.

1. Began rapidly tapping the tail switch button. After approximately 8 taps the light will no longer have any output. The exact number of taps doesn’t matter because once you have a minimum of 8 you have entered the programming mode.

2. Fully depress the tail switch so that it clicks. The light will begin slowly flashing at a reduced level.

3. Unclick the switch and then tap the switch the same number of times as the mode group you want, 6 taps for the number 6 group, or 2 taps for the number 2 group.

4. On the last click push the button all the way forward locking it on. The light will flash quickly letting you know that it has accepted the programming

After working with pflexpro he came up with a great feature for the lights. The modules I am reviewing did not come with this. With this feature you select what menu operation you want through tapping the switch but then you lock it with contacts on the led module. This allows you to have the best of everything. You get the flexibility to choose exactly what menu you want but then it is capable of being locked so there is no way to accidentally change the menu you have selected. You want high and medium, it has that. You’re too tactical for anything but high only, done. You like the tactical party atmosphere, hi and strobe is there for you.

Inside the light electronics are contacts. Typically these contacts are set and would be inaccessible once they are covered by the potting compound. Pflexpro came up with a solution where conductive posts are extended through the potting compound. The light can be locked in the menu you select by linking the contacts with conductive paint that is included with the light. This makes a semi permanent change to the light. If you want to change the selected menu you scrape off the paint, make your menu change, and then repaint the contacts. The contacts are very small and it easy to link them by using a toothpick and dabbing on the special paint.

Module on left is locked and the one on the right is unlocked.

Another option I use in my lights is a forward clicky switch. With this switch if you partially press on the button the light will come on. If you press the switch all the way forward the light locks on. If you press it all the way forward again the light turns off.

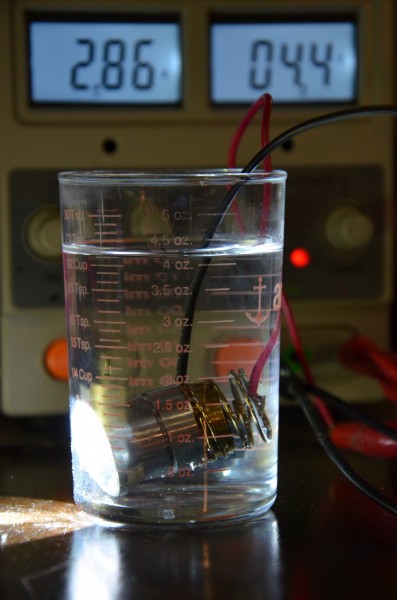

I needed the light to be durable. I occasionally drop lights or work in the rain. Pflexpro modules are fully potted. This means that a special type of epoxy is poured over the electronics once they are set in place. This makes the unit highly resistant to shock or impacts. When I was choosing options for the light I emailed Randy several times. He told me that because of the way he assembles the modules they can be fully submerged then dried off and still work. The modules, even outside of the light are water resistant.

This picture was provided by pflexpro. I repeated the test myself in the video test and had the same result. The module works outside of the host submerged under water.

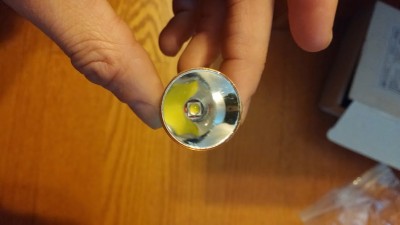

For my personal light I chose an orange peel reflector. This type of reflector gives a smooth artifact free beam. It is a very nice balance between throw and spill. The beam is a little different than many other lights, and I think it is better. It does not have a highly defined hot spot in the middle of the beam. It is much brighter in the middle and then slow dims as it moves from the center. With the exceptionally high lumen output and beam profile the light provides illumination at long distances but also works very well indoors. The beam isn’t so concentrated in the middle that it causes bounce or reflection indoors. When used indoors it is more like turning on a light in the room. The light certainly isn’t a flood style but instead a very nice combination of flood and spill.

Randy provided lights for the review with smooth reflectors. I was a little hesitant about these. Smooth reflectors can show artifacts in the beam. The pflexpro lights had absolutely no artifacts. The smooth reflector has a more defined hot spot that I would estimate as being about 15-20 percent smaller than the orange peel. The advantage of this is that it provides a little better throw when compared to the orange peel. The beam profile of the smooth reflector looks similar to other lights like Malkoff and Klarus that are using an orange peel reflector.

Both of the reflectors provide a very nice beam. If you are going to use the light a majority of the time outside for illuminating things at distance than go with the smooth reflector. If you primarily use the light indoors than get the orange peel. Ultimately either reflector will do go a great job.

Pflexpro offers several different choices of leds. Generally speaking leds in the cool range provide more output but poorer color rendition. Warmer leds give better color identification but less output. For this light I chose a U3-2A emitter. This led is advertised as having a slightly cool almost neutral tint. It is a great compromise of very high output with good color rendering. I compared the U3-2A to other led lights I have and it looks very neutral to me. No noticeable cool or warm tint, just white.

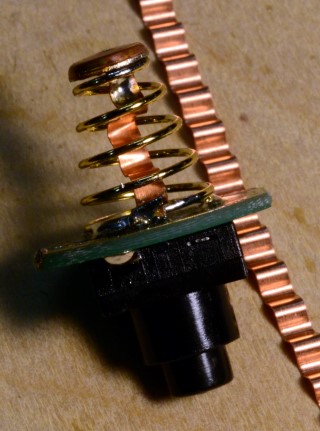

The light also comes with another pflexpro unique feature. The module has interchangeable contacts. The light includes two that are a spring with a screw that goes into the module. There are two included so that they can be replaced if one wears out.

The lights made by pflexpro are very high performance. Randy is able to safely push the led close to their limits. In order to do this the lights can only be used with 18650 sized rechargeable batteries. The lights are specifically made to work with the voltage these batteries provide. If non rechargeable CR123A batteries are used in the light it will ruin the led. This is a bit of a compromise as you are limited to only rechargeable batteries while many similar lights will take both. The tradeoff is that you get exceptional performance. In real use I have never needed to put 123a batteries in my lights that can use both types.

The lights I received from pflexpro include a 3 minute stepdown. After the light has been on high for 3 minutes the light automatically reduces output by 50 percent. If the light is turned off and then back on it will give full output. I have previously talked about how light manufactures use this feature to hide the output of their lights. Randy does not do this to mislead the buyer. In fact the lights can be ordered without the stepdown or with it set for a different time. I ordered the light with the stepdown as a battery saving feature. Keep in mind that even at 50 percent the light is making over 600 lumens. This is still an exceptional amount of light and better than many lights on the market. The stepdown is user programmable. You can’t completely turn it off but you can set it to such a long time that in practice it never activates.

Pflexpro has extensively tested the lights to make sure that they do not overheat. If you order a p60 module by itself pflexpro includes pre cut copper strips and instruction on how to install them. The strips are wrapped around the module until the module has a tight fit with the host. Randy tested several materials and found copper to outperform other materials in dissipating heat. If you order a complete light it comes with the module and copper strips installed. Because the lights are so high performance the only caveat is that if the light has no step down and it is going to be on for more than 5 minutes it needs to be hand held. For me this is an acceptable compromise and not a situation I predict I will ever run into.

Copper wrap is visible on module in the picture.

The light is engineered with two safety features. The lights come with reverse battery protection. If the battery is inserted backwards it does not damage the light, it just wont turn on. Not all lights have this and it is important to me. I have stuck batteries in backwards before. The other safety is low voltage protection. It can be dangerous to over discharge rechargeable batteries. If the batteries are drained to a set point the light will began reducing output and if they get low enough the light will turn off. I try not to ever get my batteries this low but if you do the light lets you know and prevents a dangerous situation. The only other safety feature that other lights may include is a high temperature shutdown. This is not necessary with the pflexpro lights because Randy has tested them and knows that do not exceed temperatures that would damage the light.

I had two minor issues with the lights. I received one module that I am using in my personal light. It is a surefire 6p that is bored to take rechargeable batteries. I started having issues entering and using the menu system. I contacted Randy and sent the light back. The problem was that two parts of the module are screwed together. When I installed the module in my surefire it screwed those parts together a little and that resulted in a short. Randy put a special type of glue on the threads so that it is not possible for the parts to move. The light that Randy offers tailored for police will have the threads glued together. This makes it a little harder to modify the light in the future but makes it tougher.

The second issue was with the copper strip that is used in the tail cap. The strip broke. This doesn’t stop the light from working and I only happened to notice it when I was changing a battery. Without the copper strip the light loses about 6% percent of its maximum output. The copper strip is essentially an upgrade that Randy does to the lights. He changed the strip to a different type of copper and I haven’t had any issues with it.

Pflexpro has warranty information listed on their site. Randy also explained it over the phone to me, it goes like this. You lose the light, buy a new one. The light breaks he’ll fix it.

As I stated the light can only use 18650 sized rechargeable batteries. There are dozens of manufacturers of these batteries. There are 3 main types of lithium ion batteries. Different application use different types of batteries and the reasons behind this can be very technical. Below I am going to make recommendations for several batteries. All of these batteries will achieve optimum performance out of the light. Other brands of batteries can be used if you are willing to do your own research. I highly suggest purchasing the batteries from Mountain Electronics. I have purchased batteries through them. They have very good prices and are a trusted source. Unfortunately there are many counterfeit batteries on the market but I trust Mountain Electronics to provide authentic merchandise.

Panasonic NCR18650B protected 3400mah. Highest capacity battery available. Includes built in protection on the battery. This makes the battery safer but adds another electronic component that can break.

http://www.mtnelectronics.com/index.php?route=product/product&path=59_88&product_id=55

LG ICR18650E1 unprotected 3200mah 4.35 volts. This is an unprotected battery and should never be used in a device that does not have built in protection. Pflexpro lights do have protection and it acceptable to use this battery in them. This battery has a lower rated capacity than the Panasonic but gets slightly better performance because it is a higher voltage battery. This battery must be charged in a charger than is made for 4.35 voltage batteries. The xtar sp1 is a charger that will work with this battery.

http://www.mtnelectronics.com/index.php?route=product/product&path=59_88&product_id=193

Purple EFEST IMR 18650 3100mah. This battery gives up a little capacity to the others. It is safer than the other batteries due to its chemistry. It is currently not offered by mountain electronics. It is the best battery to use if you are someone who forgets to change out batteries until the light turns off.

Best use of rechargeable batteries is to change them out before they are fully discharged and use a quality charger. The xtar mc1 is an affordable quality charger. The xtar sp1 is a good charger that can charge both the lg 4.35 volt cells and standard 4.2 volt cells.

http://www.mtnelectronics.com/index.php?route=product/product&path=79&product_id=177

There will be part 2 to this review with field testing. I have been using the light for a couple weeks and it has worked well. It does everything I need it to. The compact size works well for carrying in a cargo pocket or on a belt. For me the light is very simple to use and doesn’t have a complicated menu. At the same time the light has the flexibility that each user can tailor it their needs. If the light doesn’t have exactly what you want Randy at pflexpro can customize the light for you. If you are interested in the light take a look at http://www.pflexpro.com/product-p/apd-22m.htm

Pictures of damage after the testing.

These two photos are the tested led module removed from the host. It is undamaged. I plan to put it in a new host and continue using it.

___________________________________________________________________________________________________________________

Below I have attached some questions I asked Randy. Some of the information is technical but it is interesting if you want to know what sets pflexpro lights apart from the competition. It also shows what goes into building each light.

Are the units capable of running on high with no stepdown without overheating?

I only build flashlights that I’ve tested to run on high without stepdown*… the only requirement is that the light be handheld. Your hand serves as a very efficient heat sink. If the flashlight were running on high or laying down while running on high, after about 8 minutes, it would be too hot to handle. I’ve tested the Tj while tail standing and running on high, and the emitter was in the upper end of the safe range, but this practice is not good for the flashlight. So my recommendation is ‘high continuously while hand held and 5 minutes or less on high if it’s not hand held. The great thing about the step down set at 3 minutes, it eliminates user error. (my thought is, if there is an insulating glove being worn, it must be cold and the cold air will keep the flashlight cool…if a work type glove is being worn, it doesn’t insulate the hand from the flashlight, so the hand still serves as a heat sink). (*For power hungry users, I have started building a Direct Drive model that is only available in thermally superior host, and only sold with the step down set)

What would you say are the main features that set your units apart from others?

1. Thermal management. I spent a lot of time designing and testing the thermal systems built into the flashlight. When I started designing my drop in, I build a few mule units with thermal probes installed per Cree’s Tj measuring criteria. I sliced a finished drop in in half so I could see the internal construction of a drop in with the driver, emitter and reflector installed. I used this cutaway to as a design tool to enhance the thermal path.

Starting with the MCPCB, I use Noctigon…solid copper. Others people use Noctigon or Sinkpad, but you would be surprised at how many people don’t.

I build several things into my drop in that no one else has, or if they do have it, they’ve copied the PFlexPRO -from the top down and outside in:

–I polish the reflector shaft. If you look at the outside shaft of a P60 reflector, you will see that it has grooves. I measured the grooves and peaks and determined when you wrap a drop in, you’re only contacting 50% of the reflector shaft. I remove the grooves so that the wrapping material has full contact. The problem with machining and polishing aluminum, it instantly develops aluminum-oxide on the surface – Aluminum-oxide is a poor heat conductor. My final polishing stage is done with Arctic Silver thermal compound. The particles in Arctic Silver work well as a polishing compound and the residue grease base, even though it’s incredibly thin, stops the formation of Al2O3.

Polished reflector on the left.

–The p60 in it’s normal configuration is not very good thermally -mainly because the heat from the emitter must travel through the MCPCB to the pill platform, then down the side walls of the pill, through the threads to the reflector shaft. From there, the heat efficiently goes from the reflector shaft to the wrapping material into the host. In addition to the typical heat path, I’ve add a thermal silicone pad on the top side of the MCPCB that feeds the heat directly to the reflector. While the thermal silicone is not as efficient as metal to metal, the thermal path is much more direct…so my design takes heat from the top and bottom of the MCPCB.

–I flatten my pill platform for good contact with the MCPCB. Some enthusiasts try to sand the typically uneven platform, but sanding only makes the surface smooth, but not flat. I designed and built a special set of dies that will flatten the top of the platform and any excess metal is formed into a star on the driver side of the platform.

–I install a micro thermal pad on the bottom side of the pill platform. The emitter has a maximum junction temperature of 150°C and the driver usually has a max of 75°C. When you start adding regulators to increase the power, the electronics in the driver get very close to the very hot emitter/pill platform. The micro thermal pad stops the emitter from feeding heat into the driver.

–I install a copper heat spreader above the driver so it has an excellent thermal path to the pill and host.

–When adding regulators to increase the power, everyone else just stacks them on top of each other and solders the leads to hold them in place. The regulators generate the most heat on the driver board. If you stack them on top of each other, you’re asking for trouble (if the stacked regulators burned out, how would you know…the flashlight would become dimmer by 100 lumens, there’s no way to tell what happened). When I install extra regulators, I attach a copper heat sink between them that then runs directly to the pill. My ‘stacked regulators’ run cooler than the single regulators directly on the board.

–I use thermal silicone on the threads of the pill and reflector -this is a very important heat path.

–I supply solid copper strips to wrap my p60 drop ins with. I have also developed the ‘dual wrap’ system, which makes the wrap even more efficient. Each wrap layer creates thermal resistance, but the dual wrap system has ½ as many wraps which translates to better overall efficiency.

2. Flexibility

I have bought so many flashlights that, after a few years, are obsolete. A few years back, I sold over $1000 of 3 to 5 year old ‘off the shelf flashlights’ on ebay for $25. I make PFlexPRO flashlights very upgradable.

–I have the interchangeable spring/contact system -have you seen that on anyone other flashlight or drop in? I have different springs available for different applications and a solid contact for long protected cells in short hosts. Springs don’t last forever -especially low resistance copper alloy springs. I use two types of spring material, carbo-bronze and beryllium copper -neither of these spring types need a copper braid. There are several reasons you may need to change springs -usually because of battery fitment, but if the light is mounted on a firearm and used heavily, the spring should be replaced every few thousand rounds.

–I put a small notch on the underside of the MCPCB…only I know where it is. If someone decides to change their light to a different emitter, the notch makes it easy for me to remove the MCPCB and replace or upgrade the emitter. In five years, who knows what new emitters will be available for flashlights. My current emitter upgrade charge is $15 and includes return shipping.

–Potting while maintaining features (I will start installing my contact leads through the potting material) In the case of the 22 mode driver, changes can be enabled or disabled even though the drop in is fully potted. For the basic modes driver, mode groups can be changed even though the drop in is potted.

–Emitter choice -currently, I have 16 different emitters available for the PFlexPRO system.

3. Durability

The potting material use is very expensive and very good. Not only does it make the drop ins and flashlights very durable, I use the potting to enhance the thermal properties and eliminate ‘hot spot’ burn outs.

Soft potting materials work well for thermal management, but they actually decrease the shock resistance of a flashlight.

Why arent other manufactures getting as many lumens out of their lights with the same led?

It goes back to thermal management. It’s a lot of work and expense to add really good thermal management to a flashlight. Good thermal management allows for higher power without danger of thermal failure. Without using innovative thermal designs and the time it takes to implement…it’s safer for the big manufacturers to run the power lower and make the flashlights quickly. I’ve repaired or upgraded some of the ‘off the shelf’ flashlights and was very surprised at how little they do to manage heat. Another ploy used by many manufacturers is to step the power down after a few minutes. This way they can run it hard for the ‘big’ ANSI rating, and reduce the power before it overheats. Although some of my flashlights have ‘Turbo Step-Down’, it’s adjustable and mainly for extending battery life.

What are the basics of your process for testing the lumen output of the light?

I use an integrating sphere that I’ve calibrated using ANSI rated flashlights. For recording, I use an ANSI calibrated logging light meter. For drop ins, I wrap and install them in a Solarforce L2P host with copper wrap and a factory switch with the switch spring braided. I test using the battery I recommend for a given light. For 3.8A lights, I use either a LG E1 4.35 or an Efest 3100 IMR. For lower power lights, I use a Panasonic 3400 protected, and for higher power lights, I use an Efest 35A 2500mah battery. The battery is fully charged and off the charger for at least 1 hour. I adjust the temperature of the flashlight and battery to 23°C. The flashlight is placed in an airstream that has cooling comparable to handheld. Every flashlight is run for at least 5 minutes, recorded, graphed and shipped with the order. I also attach the drop in or flashlight to a lab power supply and reduce the voltage until the safety warning initiates -this voltage confirmation is recorded on the shipping specs.

Many lights on the market allow both non rechargeable 123a or rechargeable 18650 batteries. What is the performance result of only being able to use 18650 batteries?

The issue I have with drivers capable of handling multiple cells is efficiency and selection. If a driver has to boost the voltage or buck (step) down the voltage, it loses efficiency and also generates more heat. I also have concerns about the low voltage safety functions working properly. The protection circuit must determine if it’s running 2 nearly discharged 16350 or cr123 batteries or a fully charged 18650…these voltages may overlap and could be an issue.

Single cell led flashlights are the most efficient because the emitter voltage is just under the typical regulated voltage of a driver for a single 18650 -this means, the driver has to adjust the voltage very little to give the emitter what it needs.

There is a vast selection of drivers and features available for single cell lights

Comments

Are the pflexpro drop ins better then the malkoff drop ins? I work on airplane and always drop my lp2 from 12 foot or more and the solar force drop ins always break was going to get a malkoff then I ran across you review.